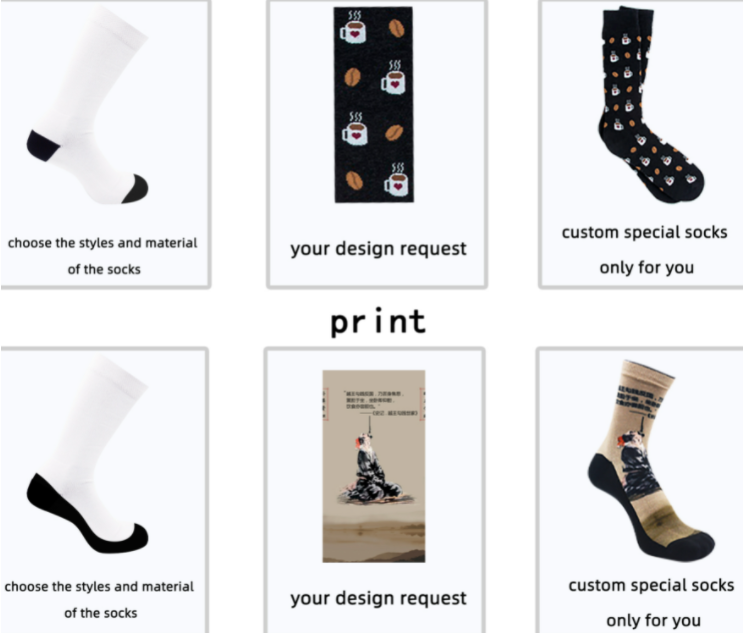

As a professional socks manufacturer, we have professional design group, providing custom service for your socks. If customer have samples, we can make it according to customer samples. If customer have no samples,we can design it according to customer idea, or customer can choose our factory samples.

The following is an introduction to socks pattern design and program making.

1: pattern design:

A pair of socks has different styles and different pattern colors. This requires design according to different needs. The form of socks design belongs to graphic design, and the format used is the creative format. It uses the presence or absence of the grid to form the overall pattern. The current design It has been replaced by a computer. Its design program principle is: convert the pattern code designed by the computer into the identification code of the hosiery machine, and control the lifting needle through the jacquard blade of the needle selector to achieve the purpose of jacquard. The common pattern arrangement is symmetrical. Asymmetric, two sides are continuous, and four sides are continuous.

What is the difference between 4F, 5F, 6F, 7F machines, F is the code name of the sock machine needle selector, 4F is the sock machine with 4 needle selectors, 5F means the sock machine has 5 needle selectors, and so on, because There are 4 or 5 needle selectors in the sock machine, so more than a dozen colors can be programmed in the same row and column in the sock. Note that two colors cannot be programmed at the same time in the same needle selector.

2: program design

A pair of socks has different stages. For example, single-needle jacquard socks are divided into nine stages, such as tie mouth, rib mouth, rib mouth, upper tube, sock heel, lower tube, bridge, sock toe, and head line, because each stage It is necessary to instruct the triangle and the guillotine to advance and retreat, which requires program design.Generally, the basic programs of semi-computer equipment and full computer equipment have been set, but when special patterns are encountered, the program needs to be re-arranged.

3: pattern making

Pattern making refers to the operation process of converting the pattern manuscript into the identification code of the hosiery machine through the computer pattern code. It includes the steps of designing the number of towns-drawing the pattern-setting the yarn path-setting the control information, etc., pattern making and program design It is closely integrated.